Update:

Building plans including foundations for three “stacks” are permitted for the Rockwool plant. Two foundations are intended for 210-feet tall smokestacks, and the third is for a 115-feet tall, 4-foot diameter “chimney,” according to Michael Zarin, Vice President of Group Communications at Rockwool, in an email to DC Media Group. When the mineral wool is cut during the manufacturing process, the chimney will vent “a small amount of particulate matter” after exhaust passes through a “de-dust” filter, Zarin says. He also says that the chimney is part of the original plans.

On August 1, 2017, the Ranson City Council passed an ordinance approved by the Building Commission which amended the building code regarding height limits. The regular height limit is 90 feet for all structures, but the regulation does not apply to certain structures such as water tanks and chimney flues. In the amended ordinance, the City Council added “stacks” to this list of exceptions.

Rockwool does not have plans for a second insulation production line, Zarin says, nor is it currently planning to manufacture acoustic ceiling tiles under the brand name Rockfon, even though the air permit from the West Virginia Department of Environment allows for the ceiling tiles.

_______

Above-ground construction of the Rockwool manufacturing facility in Ranson, W.Va., is moving forward. Concrete walls have become plainly visible at the site of the insulation manufacturing plant in recent days, and permitting shows that the company is making substantial progress toward its goal of erecting the factory amid significant local protest against it.

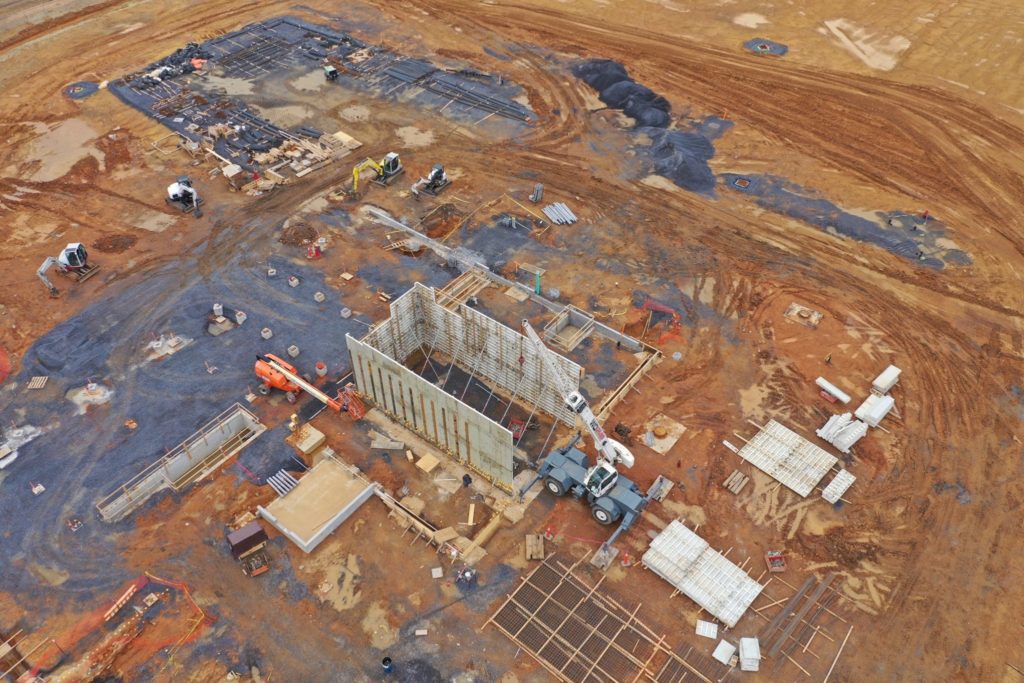

Concrete walls and a crane are visible on the Rockwool construction site. In the foreground is the area where the Mountaineer Gas pipeline is buried.

Concrete walls and a crane are visible on the Rockwool construction site. In the foreground is the area where the Mountaineer Gas pipeline is buried.On May 5, the City of Ranson issued a permit allowing Rockwool to build steel and concrete structures on the foundations for the furnace, the “cold end” building and a materials storage building. The “hot end” of the factory consists of the furnace where rock and slag are melted, the spinning chamber, oven and cooling zone, while the large, 130,500 sq. ft. “cold end” building is where slicing, dicing and packaging of the mineral wool insulation takes place.

Ranson has also issued permits for construction of underground utilities–including HVAC, electric, and plumbing–for the cold end building and the furnace.

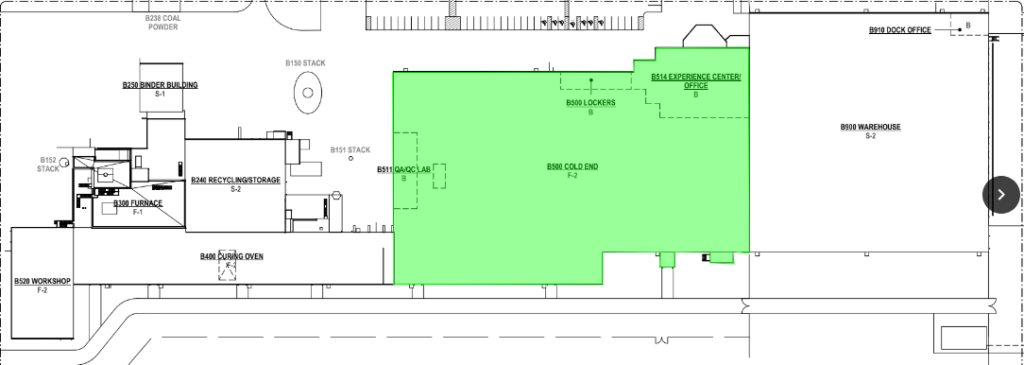

The large “cold end” building is highlighted. The furnace is on the lefthand side of the diagram.

The large “cold end” building is highlighted. The furnace is on the lefthand side of the diagram.Surprisingly, building plans showing foundations for a third smokestack have been permitted. Rockwool’s intention to erect two 21-story smokestacks has been one of the most highly contentious aspects of the factory. They will be highly visible in the valley and spoil the viewshed of the Appalachian Trail and many other tourist attractions. The possibility of a third smokestack has never been mentioned.

One explanation for the construction of a foundation for a third smokestack–and the lack of a public announcement about it from Rockwool–may be because it is preparation for expansion. Susan April, a resident of Myersville, Md. who has been researching the inner workings of the Rockwool factories, speculates that a second mineral wool production line will be added in the future.

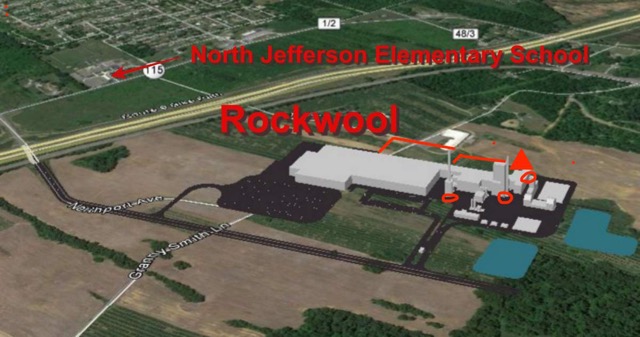

The Rockwool factory, sited across from North Jefferson Elementary School. The three circles indicate the locations of the three smokestack foundations.

The Rockwool factory, sited across from North Jefferson Elementary School. The three circles indicate the locations of the three smokestack foundations.The stack is consistent with dual production lines with the Byhalia plant and other, newer Rockwool plants abroad, she says.

“A second mineral wool line would require installing a second Aquila furnace and a second gutter zone parallel to the present one,” she told DC Media Group in an email. “Both could use the single larger flue-gas cooling tower stack that sits separately in the diagram [pictured above].” April stresses that she is not an architect or a civil engineer.

The possibility of a third smokestack has not been confirmed by Rockwool.

A view of construction from the air on May 11/Photo by Brent Walls, Upper Potomac Riverkeeper

A view of construction from the air on May 11/Photo by Brent Walls, Upper Potomac Riverkeeper

2 thoughts on “Ranson Gives Rockwool Go-Ahead for Vertical Construction”